By MSS Clean…

Cleanroom Design and Fit Out Services

MSS has more than two decades of experience in the innovative yet cost effective design and installation of a wide range of cleanroom facilities, where sterile environments are critical for clients’ successful operations and businesses.

MSS has more than two decades of experience in the innovative yet cost effective design and installation of a wide range of cleanroom facilities, where sterile environments are critical for clients’ successful operations and businesses.

These facilities range from Microbiological Laboratories to ACDP category 3 & 4 containment suites, Packaging Halls to Aseptic Suites.

MSS Design Teams include host building architectural experts as well as specialists in cleanroom systems, components, HVAC design, electrical and mechanical systems and CAD Technicians. Together, they can offer responsive services and effective solutions based on comprehensive understanding of individual clean room facility requirements.

MSS provide a consultancy service to review existing HVAC, Chilled Water and associated utilities offering suitable cost effective solutions for upgrades etc. The company can also undertake certified inspection and repair of existing clean room enclosures for integrity performance.

Pharmaceutical Cleanroom Design must comply with various design guidelines and standards. These all need to be factored in to the overall design before finalising choices on individual cleanroom systems and components.

The new ISO standard defines a cleanroom as:

“A room in which the concentration of airborne particles is controlled, and which is constructed and used in a manner to minimise the introduction, generation, and retention of particles inside the room, and in which other relevant parameters, e.g. temperature, humidity, and pressure, are controlled as necessary.”

The fundamental issue is the concentration of airborne particles in the cleanroom. Particles can be affected by every component that has contact with the cleanroom, from the mechanical and electrical components down to the type of paper that may be used and including everything in between: walls, floors, ceilings, how the structure integrates with other components, and so on.

Standards Compliance

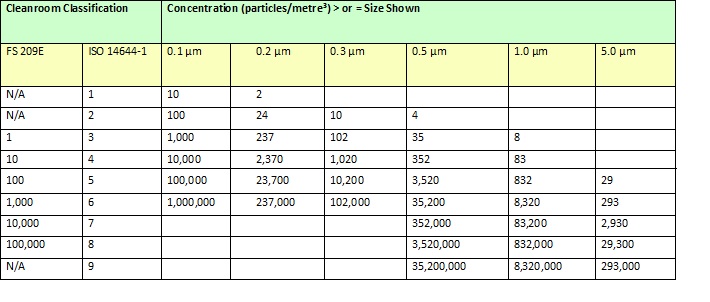

Cleanroom are classified using ISO standards (although older standards are frequently referenced and should be known). These standards are based on the maximum number of airborne particles greater than or equal to 0.5µm in diameter that may be present in a cubic metre of room air.

The cleanroom and controlled environment classification chart below details the ISO standard 14644-1 alongside the more commonly referenced Federal Standard 209E.

Fit Out Services

MSS provide specialist fit out and cleanroom installation for Controlled Environments, Cleanrooms and high containment laboratories. It has also developed proprietary cleanroom ceiling and wall systems to meet the highest standards and classifications demanded by the Pharmaceutical and Biotechnology Industries.

We can provide systems with flush, non-particle-shedding surfaces, tough maintenance-free cleanroom finishes, long life expectancy and flexibility to allow for clean room reconfiguration or relocation.

Other options include:

• Walk-on cleanroom ceilings – walk-on capability for maintenance outside of clean area

• 50 mm thick Modular Cleanroom Wall System – maximising cleanroom space

• Flush Clean room Windows and Glazing Options

• Flush Clean room Door Frames

• Sterile and Cleanroom-rated Fixtures, Fittings and Benching

• Choice of Door Leaf finishes– in stainless steel, GRP, steel or laminate

The MSS system can also be utilised cost effectively for laboratory fit outs.

For more information on MSS cleanroom design and fit out services or to discuss your requirements, please contact MSS directly.